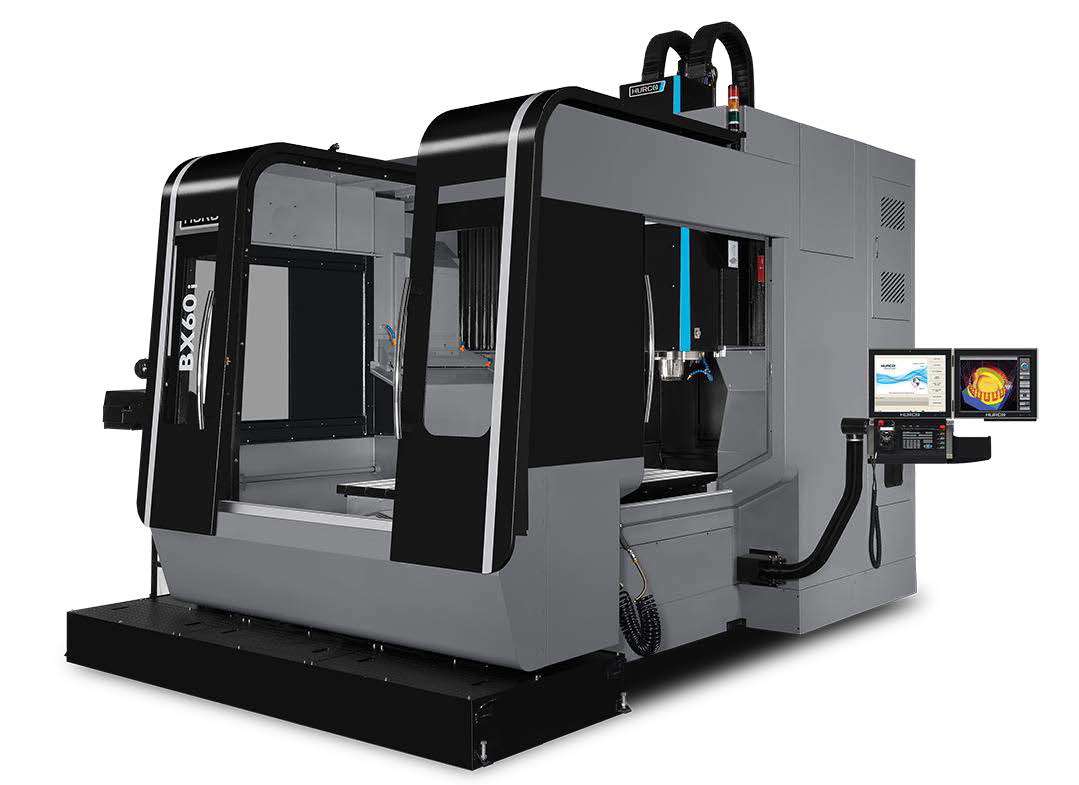

New Hurco BX60i/30ATC Double Column CNC Machining Centre 3-Axis (11301)

HSK63 A, Bed 1900 x 1300, 35kW, 20,000 rpm

Availability: Ex-import

Price: POA

Where expert design and advanced technology meet. The double-column design provides extreme rigidity and outstanding support for the head to take machining to the next level and deliver the highest performance capabilities to any machining application.

NEW i Features

| New enhanced graphics package,1.4 x faster | Superb NEW MAX5 control |

| Ultimotion, reduces cycle time up to 30%. | Improved LED cabinet lighting |

| Enhanced Version 10 software | New solid state hard drives |

| Stunning all NEW ergonomically designed machine surround | Optional Ultimonitor incorporates Ultinet (networking) and ESF (Extended Shop Floor) capability of remote diagnostics |

Basic Machine Specifications

Capacity:

| X, Y, Z axis Travel | 1,600 x 1,300 x 700mm |

| Table Working Surface | 1,900 x 1,300mm |

| Table T - Slots | 8 off x 22mm @ 160mm centres |

| Maximum Machine/ Rotary Table Load | 6,000 Kg |

| Spindle Nose to Table (min-max) | 180mm / 880 mm |

| Coolant capacity with conveyor | 900 litres |

Spindle:

| Spindle Taper | HSK63 A |

| Spindle Speed | 20,000 RPM with spindle chiller |

| Spindle Motor Horsepower (1 min. rating) | 47 HP (35 kW) |

| Spindle Motor Torque (1 min. rating) | 119 Nm @ 2800 RPM |

| Hurco machine tools require that the tool holders used must be balanced to a rating of G2.5 for up to 30,000RPM. Utilizing tooling that does not meet these specifications could affect the machine warranty. | |

Motion:

| Rapid Traverse Rate X,Y,Z | 36/36/36 m/minute |

| Cutting Feed Rate X,Y,Z | 36/36/36 m/minute |

| Positioning Accuracy Linear | 0.010mm |

| Repeatability Linear | 0.005mm |

ATC

| Number of Stations | 30 |

| Tool to Tool ATC Time | 2.5 Seconds |

| Tool Changer Type | Electronic |

| Maximum Tool Diameter (max with adjacent sides empty) | 80mm (150mm) |

| Maximum Tool Length | 300mm |

| Maximum Tool Weight | 7 KG |

Size:

| Maximum Operating Dimensions (approx.) | |

| Machine Weight | 20,000Kg |

| Machine Shipping Weight | 22,000 Kg |

| Shipping Dimensions (W x D x H) | 4,500 x 3,500 x 3,550 mm |

| Voltage Required / Fuse rating | 3-phase 380V/415V 50 Hz/ 150 amp D rated MCCB |

| Power Rating / Full Load KVA | 62.74 KVA |

| Air Requirements | 5 CFM @ 80-100 PSI / 0.14 M3/min. @ 6-8 bar / 0.1 connected via a 12mm nylon push fit fitting |

Standard Machine Features:

| Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA) | Pistol-style Coolant and Air Guns |

| Wedge-locked Heavy duty Linear Rails for X, Y & Z Axes | Metal Telescopic Way Covers |

| Roller Linear Guideways for even more rigidity | Automatic Central Lubrication System |

| Direct Drive Servos on X,Y & Z axis | Power Cabinet Heat Exchanger |

| Z axis with Regenerative Brake - No Counterbalance | Way Lube Separation System |

| Double-nut Pre-tensioned Ballscrews Anchored at Both Ends | Modular One-Piece ITX Control Rack |

| 18,000 RPM AC Spindle Motor | 2.7GHz Dual Core Processor |

| Air Purged Chrome-moly Alloy Cartridge Spindle with ABEC Class 7 Bearings | 4 GB RAM Memory |

| Yaskawa Sigma V Digital AC Servos | 128 GB Solid State Hard Drive |

| Fast 36 m/min X,Y,Z Rapid Traverse | 12 Months Parts and Labour Warranty |

| Electric Swing-arm 30 Station ATC - Random Access | Spindle chiller |

| 2.5 Second Tool-to-Tool ATC Time | Chip / Swarf conveyor |

| Door Safety Interlocks / ANSI B11.23 | Coolant wash-down |

| Full Enclosure with Wide Front Access and Side Access Doors | Height adjustable Winmax control |

| LED Work Light | 3-stage signal light |

| Flood & CTS Coolant Systems |

Standard Accessories:

Finite Element Analysis

Roller Type Linear Guideways

Linear Scales

Double-nut Ballscrews

20,000 RPM High-Speed Motorized Spindle

Yaskawa Sigma V Digital Drives

30 Station ATC

Flood Coolant

Coolant Thru Spindle

ITX Technology

Spindle chiller

Chip/Swarf Removal

Machine Options:

Mist Extraction Unit

Part Probing

Tool Probing

Basic Remote Jog - Standard

LCD Remote Jog (optional)

Wireless LCD Remote Jog (optional when it

becomes available)

TERMS OF SALE.

- Commissioning, hydraulic oil and transportation for new and used machine(s) are for the buyers account unless otherwise specified in writing by TH MACHINE TOOLS CC.

- All goods must be paid in full before collection or delivery, unless otherwise specified in writing by TH MACHINE TOOLS CC, who reserves the right to charge interest on all overdue amounts.

- All goods remain the property of TH MACHINE TOOLS CC until paid in full.

- ALL DELIVERIES are at the cost of the buyer.

- ALL DELIVERIES exclude foundation preparation, anchoring and electrical connection unless otherwise specified in writing by TH MACHINE TOOLS CC.

- GOODS DELIVERED remain the property of TH MACHINE TOOLS CC until fully paid for and we retain the right to repossess and remove any goods supplied at our own discretion, holding the buyer liable for any additional costs deriving directly from such removal and or damages inflicted to the goods while such goods were used by the buyer.

- GOODS TRANSPORTED in any other way than our own transport are in transit at the buyer’s risk which hereby does indemnify and hold us blameless against any claim which he may have in respect of damages or any other cause whatsoever.

- One day machine operational training is included with all new CNC / NC machine purchases plus an extra two days application training with new HURCO machine purchases. Additional training is available at the cost of the buyer.

- A warranty is offered on all new machines from date of collection / delivery against faulty material and/or workmanship excluding electrical components and hydraulic seals.

- Industrial machines: Twelve (12) months warranty.

- Light-duty machines: Six (6) months warranty.

-

The warranty will be invalidated under the following conditions:

- Breakdown /malfunction caused while operating machine outside factory capacity specifications.

- Breakdown /malfunction caused by third party electrician / technician.

- Breakdown /malfunction caused by operator error.

- Breakdown /malfunction caused by fair wear and tear.

- In case of a warranty call-out the buyer will be responsible for all traveling expenses exceeding a 100 kilometer radius as well as all accommodation expenses.

- All out of warranty call-outs are charged Rand per hour + Rand per kilometer. Time begins at the point of departure and ends upon point of return.

- All used / reconditioned machines are sold “As Is”, unless otherwise specified and a Working Warranty is issued in writing by TH MACHINE TOOLS CC.

- TH MACHINE TOOLS CC does not warrant to the buyer that the tooling are fit for the purpose sold and/or are free from any defects whether latent or patent.

- TH MACHINE TOOLS CC will endeavor to pass on the benefit of any manufacturer’s guarantee but apart there from there shall be no liability whatsoever attaching to TH MACHINE TOOLS CC.

- Prices are subject to change due to currency fluctuations and/or increases imposed by our supplier.

Prices excludes delivery.

Send us a request for quotation if you want us to deliver.

Our fleet of bakkies and rigging trucks enables us to provide a comprehensive range of delivery and rigging services.

We also work with other reputable transport companies for all long distance transport and export services.

Send us a request for quotation if you want us to deliver.

Our fleet of bakkies and rigging trucks enables us to provide a comprehensive range of delivery and rigging services.

We also work with other reputable transport companies for all long distance transport and export services.

For finance options please click here.

Send Enquiry

3 Axis Brochure 2023.png)